Important Notice

We use cookies to provide an optimal experience on our website. By continuing to use this website, you accept the use of cookies.

Trouble-free operation, with the lowest cost of ownership.

Centrifugal air compressors also referred to as dynamic compressors, are designed to produce large volumes of compressed air in an extremely energy efficient process. Although manufacturers that require over 200 to 250 total horsepower tend to realize the greatest savings, all industrial manufacturers should consider the advantages of centrifugal technology.

The risk of trace oil reaching the finished product or oil contamination in equipment lines leading to higher maintenance and downtime is avoided with a centrifugal compressor. Condensate generated from a centrifugal compressor is not subject to the same local regulations as oil-contaminated condensate, allowing for easy and low-cost disposal.

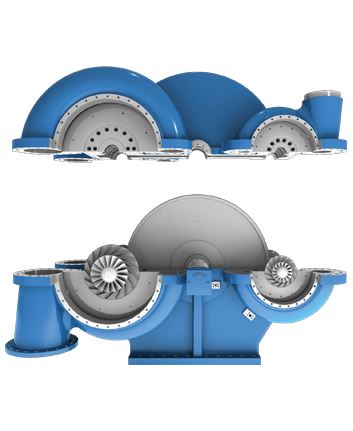

Centrifugal compressors do not rely on wearing surfaces to create compression, leading to longer-lasting bearings and other rotating components. The number of extra components such as oil and filters are drastically reduced saving material and labor costs. FS-Elliott air compressors take maintenance-friendly operation a step further by offering a horizontally split gear case, allowing full access to the gearbox in the field and avoiding costly downtime.

Available in up to four stages, centrifugal air compressors are on average 5% more efficient than older compressor designs. As the number of stages increases, the compression ratio is lower, meaning higher efficiency.

Discover how much it costs to operate your current system, compared to what you could be paying by employing a centrifugal air compressor.

Understanding the benefits is the first step in reducing your compresed air costs.